Manufacturers Of Fire Resistant Sleeves & mattes

High Grade Silicone Rubber Bonded to Woven Fiberglass Matting

PHYSICAL PROPERTIES

| Coating | High Grade Flame Resistant Silicone Rubber |

|---|---|

| Weight, oz/sq yd, nominal | 96 |

| Thickness, inches, nominal | 0.125 |

| Flame Resistance | Excellent |

| Oil and Hydrocarbon Resitance | MIL-C-20696, Sect. 4.2.4 |

| Abrasion Resistance | Excellent (Silicone side) |

| Temprature Rating: | |

| Coating: | -65°F to 500°F continuous; transient exposure to 600°F |

| Base Fabric: | 1000°F/540°C continuous |

| Base Fabric can be certified to: | MIL-Y-1140 |

| MIL-I-24244 | |

| Finished Product can be certified to: | MIL-I-24244 |

| ASTM E84.84A | |

| ASTM E162 |

REX Silicone Sleeve & Tape is designed to protect hoses, wires and cables from the hazards of high heat and occasional flame. It protects continuously to 260 °C / 500 °F and will withstand a molten splash at 1200 °C / 2200 °F. Made of knitted fiberglass yarns in a flexible substrate, it is then coated with a high grade silicone rubber.

Resistant to hydraulic fluids, lubricating oils and fuels, REX Silicon Sleeve & Tape insulates against energy loss in piping and hosing, protects employees from burns and allows “bundling” of wires, hoses and cables.

The Braided version allows qualified hose assemblies to pass AS1055D testing under stated flow and pressure conditions.

PHYSICAL PROPERTIES

| Fiberglass Type E | Silicone Rubber | |||

|---|---|---|---|---|

| Breaking Tenacity | 1.71 gf/TEX Std and Wet | Durometer, Shore A | Initial | 35 |

| Tensile Strength | 450,000 – 500,000 psi | Aged 240hrs @ 200°C | 45 | |

| Breaking Elongation | 4.81% Std and Wet | Tensile Strength | Initial | 875 |

| Elastic Recovery | 100% | Aged 240hrs @ 200°C | 800 | |

| Average Stiffness | 2824.3 cn/TEX | Elongation % | Initial | 500 |

| Effect of Heat | Will not burn | Aged 240hrs @ 200°C | 200 | |

| Retains 75% tensile at 343°C | Flammability, UL94 | V-1 | ||

| Softens at 732 -877 °C | Dielectric Strength (Volts/mil) | 485 | ||

| Melts at 1121 – 1182 °C | ||||

| Effects of Acids and Alkalis | Resistance to acids is fair Good resistance to most alkalis | |||

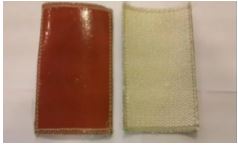

REX Silicone Shield with a Hook and Loop Closure is designed to protect hoses, wires and cables from the hazards of high heat and occasional flame. It protects continuously to 260 °C / 500 °F and will withstand a molten splash at 1200 °C / 2200 °F. Made of woven fiberglass yarns in a flexible substrate, it is then coated with one side high grade silicone rubber.

Its unique Hook and Loop Closure allows application in-situ without the need to dismantle and reconnect fittings and terminations. Repair of existing installations is performed with a minimum of labor and downtime.

Resistant to hydraulic fluids, lubricating oils and fuels, REX Silicon Shield with a minimum average weight per square yard of 96 ounces, insulates against energy loss in piping and hosing, protects employees from burns and allows shielding of induction furnace cables from splashes of molten metal.

PHYSICAL PROPERTIES

| Coating | High Grade Flame Resistant Silicone Rubber |

|---|---|

| Weight, oz/sq yd, nominal | 96 |

| Thickness, inches, nominal | 0.125 |

| Flame Resistance | Excellent |

| Oil and Hydrocarbon Resitance | MIL-C-20696, Sect. 4.2.4 |

| Abrasion Resistance | Excellent (Silicone side) |

| Temprature Rating: | |

| Coating: | -65°F to 500°F continuous; transient exposure to 600°F |

| Base Fabric: | 1000°F/540°C continuous |

| Base Fabric can be certified to: | MIL-Y-1140 |

| MIL-I-24244 | |

| Finished Product can be certified to: | MIL-I-24244 |

| ASTM E84.84A | |

| ASTM E162 |

Enquiry Form

For Samples & Quote Request