Manufacturers Of Graphite Sheets & Rings

- Graphite Sheet with SS Wire Reinforcements

- Graphite Sheet With SS 304 / SS 316 Tanged Reinforcements

- Graphite Sheet with Tin Reinforcements

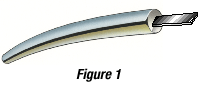

Slade starts with special patented yarns. The yarns are reinforced with flattened strips of stainless steel and totally encapsulated in flexible graphite (fig. 1). We “weave” these yarns into sheets 80” wide (lengths: 80”, 160” and higher).

| Properties | Pressure | Sizes | PH | Temp | Thickness |

|---|---|---|---|---|---|

| Ranges | 4,500 PSI (310 BAR) | 80″ X 80″ and 80″ X 160″ | 1-14 | -400°F (-240°C) to 1800°F (1000°C) | 1/16″, 3/32″ and 1/8” |

Step 1:

Construction of Weaving Yarns: Flat metallic leaf springs of stainless steel encapsulated in a thick graphite foil jacket.

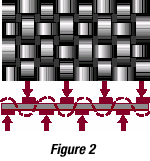

Step 2:

Yarns are woven into a tough, resilient cloth-like sheet. The stainless steel reinforced yarns crisscross throughout the cloth to impart tremendous strength and resiliency to the sheet and gaskets cut from the sheet.

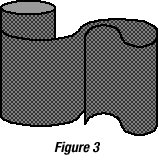

Step 3:

The woven sheets are compressed to increase density to form a leak-tight gasket sheet, ready to cut. The sheets are flexible enough to roll for shipping and storage.

- Densities -1.1 g /cc -1.9 g /cc

- Carbon content -99% -99.85%

- Chloride cont: 50 ppm max

- Sulphur content: 1300 ppm

- Fluoride content: <30 ppm

- Ash content: 0.5 % max

- Thickness:0.1~0.8mm

- Length:30~60m

- Density: 0.7~1.2

- The tensile strength: ≥4.2mpa

- Sulphur Content: ≤1000PPM

- Chlorine Conten: ≤50PPM

| PHYSICAL PROPERTIES | ||||

|---|---|---|---|---|

| Standard Carbon Content | 99% | |||

| Density Range | 1.2 g/cc to 1.8 g/cc | |||

| Temperature | -200°C to + 2,800°C in inert or reducing conditions | |||

| -200°C to + 500°C in oxidizing conditions | ||||

| Tensile strength | ASTM F152 >5.2Mpa | |||

| Compressibility | 47% | |||

| Recovery | ASTM F36/A >9% | |||

| Chloride content | 50 ppm maximum | |||

| Suphur content | 1300 ppm | |||

| Fluoride content | < 30 ppm | |||

| Ash content | < 1.0% | |||

Enquiry Form

For Samples & Quote Request